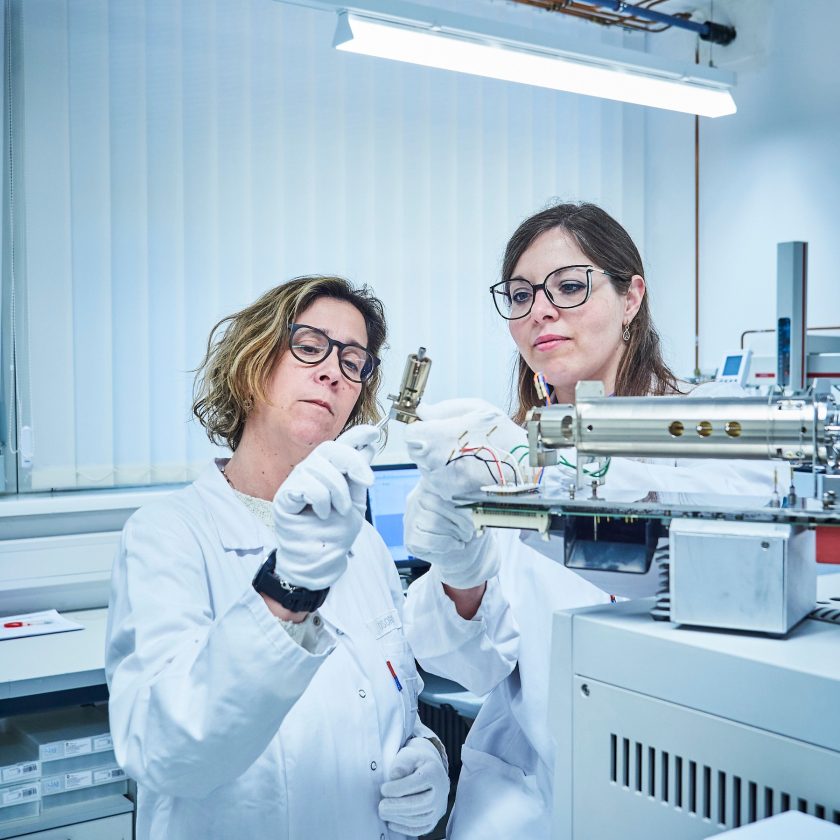

Type examination for approval

Dangerous goods transport packaging must be subjected to type testing before it is used for the first time in accordance with the applicable legal situation (ADR, RID, IMDG Code, ICAO-TI, UN Recommendations). In the process, the packaging design is subjected to various load tests.

We perform the following tests for you:

- Chemical resistance test

- Permeability test

- Hydraulic test

- Leak test

- Stack pressure test

- Case Review

The OFI is authorized to issue internationally valid UN approvals for tested packaging and IBCs (abbreviation: “A/PA-03”). On the basis of this authority, appropriate approvals can be issued immediately after completion of the type examination.

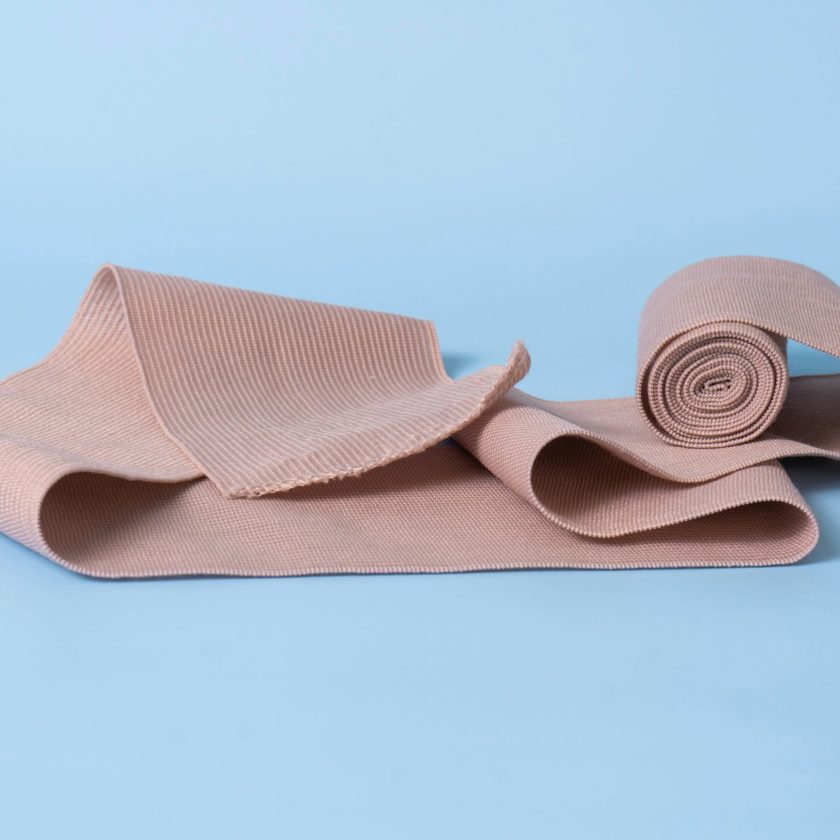

From canisters to big bags

A wide range of different types of transport packaging and large packaging materials are studied at the OFI. In addition to type tests for packaging, the OFI offers the following tests for large packaging:

- Lifting test from below

- Lifting test from above

- Stack pressure test

- Tilt drop test

- Set-up test

- Tear test

- Vibration test

In addition, we offer the following tests according to ISO 21898 for FIBC that are not to be used for dangerous goods:

- Cyclic lifting test

- Compression test

- UV test

Ongoing monitoring

Once a dangerous goods package is approved for the market, the legislation states that continuous quality control must take place, including annual inspection by an external, independent auditor. As an accredited inspection body, OFI can perform this monitoring for you. Production is inspected directly at the customer’s site, procedures are explained and processes are scrutinized.